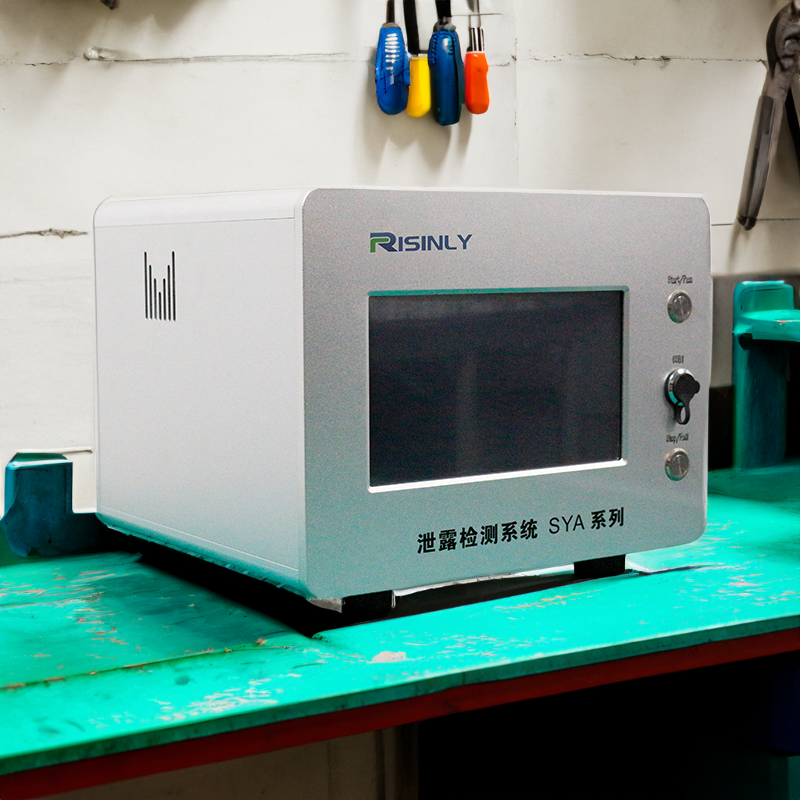

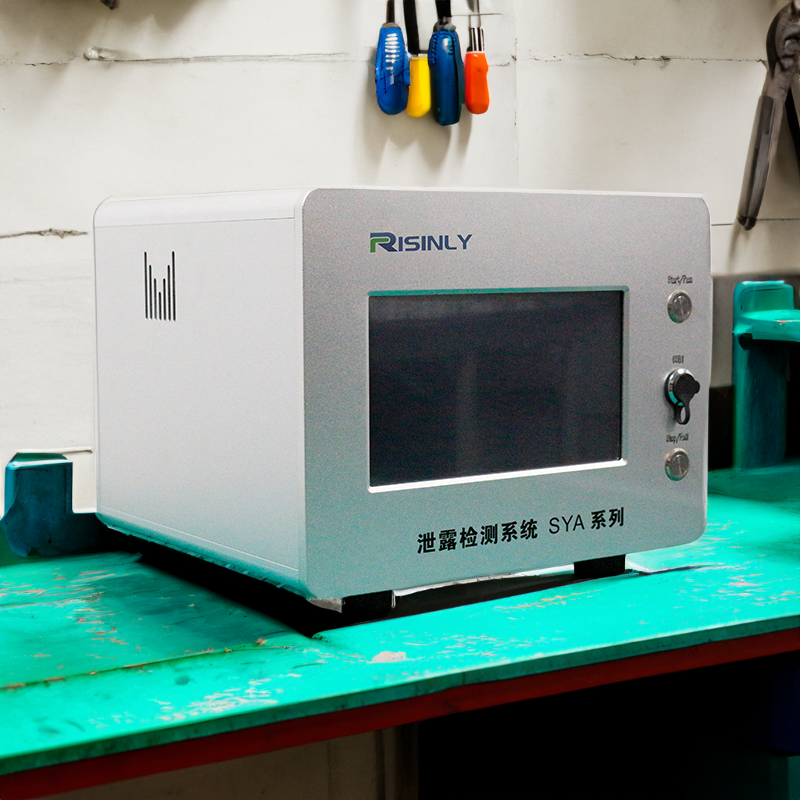

Direct pressure air tightness detector

The steps of the direct pressure air tightness detector are generally as follows:First, the power supply of the detector is connected to the socket, and the air source of the air compressor is connected to the air source of the detector. The test tube of the detector is then connected to the product's air filler or, if the product has no air filler, to the tooling fixture. Then, turn on the power switch of the detector, select the corresponding test program, and start the test. After the test is completed, the detector will automatically stop and display the test result. If the test passes, it will display PASS; if the test fails, it will display FAIL.

The steps of the direct pressure air tightness detector are generally as follows:

First, the power supply of the detector is connected to the socket, and the air source of the air compressor is connected to the air source of the detector. The test tube of the detector is then connected to the product's air filler or, if the product has no air filler, to the tooling fixture. Then, turn on the power switch of the detector, select the corresponding test program, and start the test. After the test is completed, the detector will automatically stop and display the test result. If the test passes, it will display PASS; if the test fails, it will display FAIL.

1. Automotive industry: air tightness testing of automotive lights, engine parts, vehicle cameras, charging piles, charging guns and other products.

2. Consumer electronics industry: waterproof testing of sports audio, Bluetooth speakers, hair remover, electric brush, electric bath head, mobile phone and other products.

3. Household appliances industry: washing machine, refrigerator, air conditioning and other products sealing performance testing.

4. Outdoor security industry: waterproof performance detection of cameras, alarms and other products.

5. New energy industry: sealing performance testing of solar panels, wind power generation equipment and other products.

6. Medical device industry: air tightness testing of medical catheters, syringes and other products.

7. Metal die casting industry: air tightness testing of various metal products.

8. Plastic shell industry: air tightness testing of various plastic products.

9. Food packaging industry: sealing performance testing of food packaging bags, bottles and other products.